P e x s u p p l y. 4 7 7 4 PEXSUPPLY RESOURCES GPM Chart for Copper & PEX Pipe Tubing Size/Type Minimum Flow Rate1 (gpm) Maximum Flow Rate2. DESIGN GUIDE Residential PEX Water Supply Plumbing Systems Prepared for Plastics Pipe Institute, Inc (PPI) 105 Decker Court Suite 825 Irving, TX 75062. For 1' tubing connections, Uponor’s ProPEX fitting has 12% greater internal diameter (i.d.) and 25% greater gallons-per-minute (gpm) flow rate than an insert fitting. This is particularly important with the increasing use of PEX in residential fire sprinkler systems, where lower-flow fittings may require larger tubing sizes and additional. These suggested tubing sizes are based on a 20 degree temperature drop using a 50/50 water/glycol blend. Flow rates are assumed to be 10 gpm for the category 1 boilers, 14 gpm for the category 2 boilers, 18 gpm for the category 3 boilers, and 20 gpm for the category 4 boilers (See the formula at the end of this document to see how these flow rates are derived). The valve sizes on the manifold indicate the largest compatible PEX tube size. For example, if the manifold has 3/4-inch valves, you can install 3/4-inch, or smaller, PEX tubing. Reducer fittings.

Tubing is an essential part of every hydronic radiant heating system. Like veins, it transports warm fluid, and the heat output, throughout your floors, turning them into comfortable, warm surfaces. We offer the best PEX and PERT tubing for our hydronic systems, available in a variety of sizes, ranging from 3/8″ to 1″. These tubes provide excellent performance in radiant applications and provide the system designer with the greatest options for component selection. With five sizes available, how do you know which one is best for your project? These general rules can help.

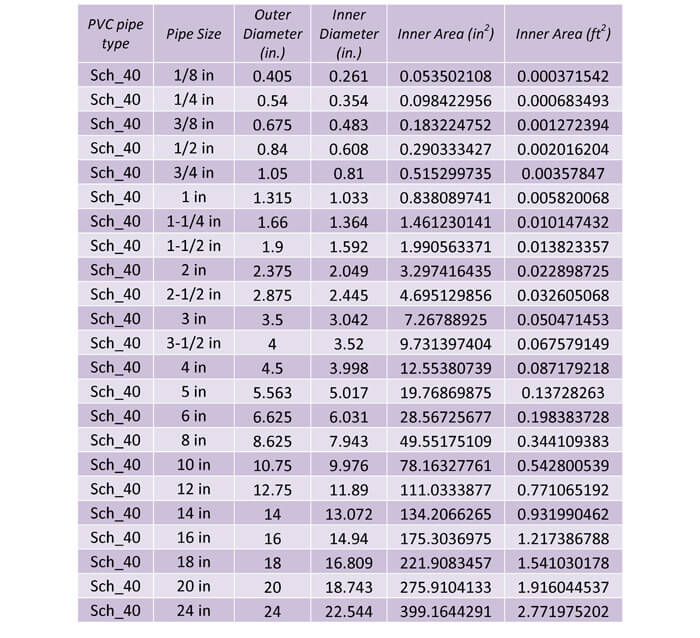

PEX and PERT tubing come in several different sizes. The most common sizes are 3/8″, 1/2″, 5/8″ and 3/4″. Generally, for a residential Infloor Heating System® we recommend 3/8″ and 1/2″ tubing. The tube size dictates the flow rate that can be achieved and also indicates the maximum loop length based on the head pressure. We generally recommend 5/8″ and 3/4″ tubing for large commercial and snowmelt applications.

Factors such as tubing size, tube spacing, and water temperature directly represent the heat output (in BTH/sq. ft./hr.) of the radiant heating system. The later is especially important, since heat loss calculations is the initial stage of every radiant heating project and allows the installer to determine which tubing size to use and how long the maximum length would be.

To increase the floor output for selected tubing size and length, the flow may need to be increased, the tubing spacing may be closer together, or an increase in water temperature. For example, by increasing the flow through 1/2″ PEX tubing by only 0.1 GPM, floor output will increase at 5 BTU/sq. ft./hr.

With 1/2″ tubing, a 6″ pattern is sometimes used in smaller spaces, such as bathrooms, and for extreme cold climates, while 8″ and 9″ patterns are standard for most living areas in most climates, and a 12″ pattern is used in garages. For most large shops and small commercial applications 5/8″ oxygen barrier PEX or InfloorPERT® tubing is typically used. With 5/8″ tubing a 9″ to 12″ pattern is standard. For large shops and large commercial buildings (usually over 5,000 square feet) 3/4″ oxygen tubing is standard. With 3/4″ tubing either a 12″ or an 18″ spacing is used, depending on the climate and the desired temperature for the space.

Pex Sizes Gpm Chart

Now that you’ve chosen a size and spacing of tubing for your project, simply multiply the square footage of the space to be heated by one of the following multipliers to determine the overall lineal footage of pipe that you will need. Be sure to use the correct multiplier that corresponds to the spacing you have chosen:

6″ spacing = sq. ft. x 2.0

8″ spacing = sq. ft. x 1.5

9″ spacing = sq. ft. x 1.34

12″ spacing = sq. ft. x 1.0

18″ spacing = sq. ft. x .67

Once you have determined the actual combined length of tubing you will need, the next step is to determine the number of loops or circuits of pipe. With 1/2″ tubing a circuit length of 300′ is standard, but circuits anywhere from 250′ up to 350′ are within the range recommended by the Radiant Panel Association. With 5/8″ tubing 400′ and 3/4″ tubing 500′ circuits are standard. For example, if you are using 1/2″ tubing and have determined you will need 900′ of tube, you will have three circuits of 300′ each and a three port manifold. If you are using 5/8″ tubing and have determined you will need 3000′ of tube, you will have eight circuits of 375′ each and an eight port manifold.

We can answer any design questions you have. We also offer a free design service as part of the systems we sell. Contact us today to get started. www.infloor.com

Maximum Tubing Run Lengths:

3/8″ Tube loops should not be over 200′

1/2″ Tube loops should not be over 300′

5/8″ Tube loops should not be over 400′

3/4″ Tube loops should not be over 500′

Pex Sizes Guide

Join our online community and stay in the loop with Infloor Heating Systems: